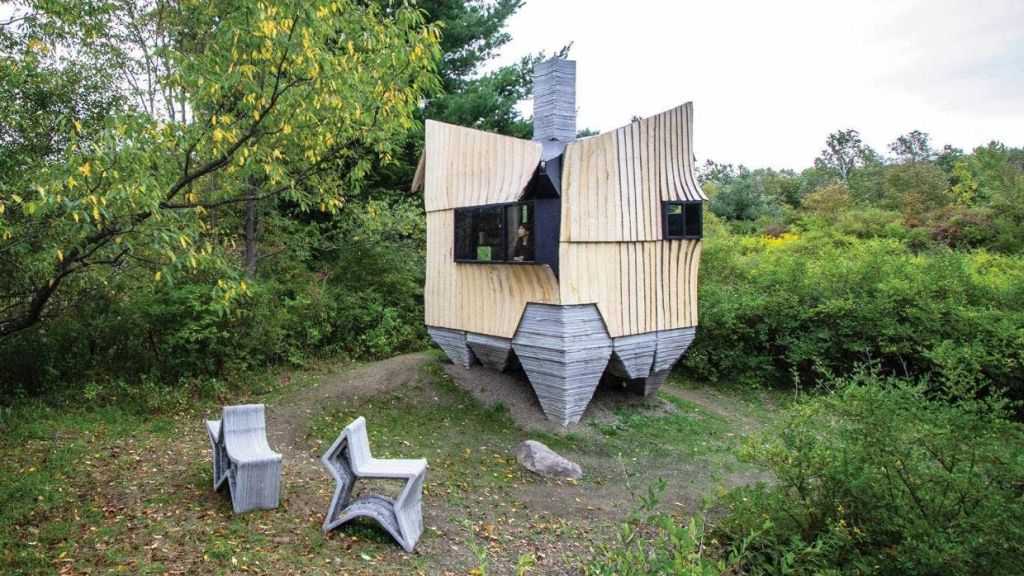

Borer-infested wood gives this tiny cabin a fairytale presence

Wood infested with borer is usually destined for the fire – after all, what possible use could it have?

Turns out, once treated, it can be used to build houses sustainably, as this project demonstrates.

This cabin in the woods was built from native ash, a timber that is being devastated throughout New York State by an emperor ash borer beetle infestation. The beetle, thought to have been in the state for nearly 20 years, is threatening 8.7 billion trees.

Leslie Lok and Sasa Zivkovic, assistant professors of architecture at Cornell and co-principals of their design firm, Hannah, have designed and constructed a full-scale prototype cabin home in rural Upstate New York that responds to the environmental crisis. Ashen Cabin advances the use of technologies, such as robotics and 3D printing, in timber and concrete construction.

They believe the prototype offers a new way to think about the future of home construction.

The pair say that until recently, mature ash trees compromised by the ash borer have not been usable by conventional sawmills as a source of lumber for home construction, in part because of their irregular geometries.

“Infested ash trees often either decompose or are burned for energy,” says Zivkovic. “Unfortunately, both scenarios release CO2 into the atmosphere. The advantage to using compromised ash for construction is that it binds the carbon to the earth, and offsets the harvesting of more commonly used wood species.”

“Infested ash trees are a very specific form of waste material, and our inability to contain the blight has made them so abundant that we can – and should – develop strategies to use them as a material resource.”

Zivkovic is also director of the Robotic Construction Lab (RCL) at Cornell, where the team built a custom robotic platform for the sole purpose of processing the irregular ash trees.

“Basically, we begin by creating 3D scans as a basis for translating and digitising the complex and irregular geometries of the mature trees,” he says. “The robot is then programmed to cut and process irregular wood geometries.”

The machine the team used was found on eBay, and had formerly been used to build cars for General Motors.

“We know that concrete is responsible for 8 per cent of total CO2 emissions,” Lok says. “By using 3D printing, we eliminate the use of wasteful formwork and can deposit concrete smartly and only where structurally necessary, reducing its use considerably while also maintaining a building’s integrity.”

Zivkovic and Lok hope the project’s combined environmental concern and inventive use of advancing technologies will to inspire imaginative design, improve material efficiency in construction, and reduce long-term construction costs.

They also hope it will increase the availability and versatility of tools for distributed manufacturing that offer unprecedented mass customisation to future homeowners.

- This story originally appeared on stuff.co.nz

We recommend

We thought you might like

States

Capital Cities

Capital Cities - Rentals

Popular Areas

Allhomes

More