Breakthrough in 'green cement' promises to help cut emissions from concrete, a major polluter

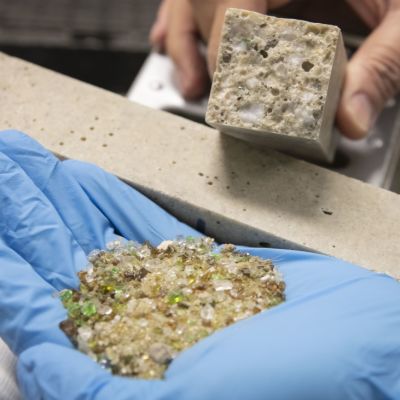

A type of cement touted as more environmentally friendly than the conventional version is a step closer to being used in home building, after a new discovery by Sydney researchers.

A carbon-neutral variation of cement had struggled to gain widespread adoption because of its poor water resistance.

The new breakthrough promises to make this greener type of cement as robust as its traditional counterpart.

Known as magnesium oxychloride cement, or MOC, this version is carbon neutral, as opposed to conventional cement which emits carbon dioxide in the chemical reaction in which it is made.

The bulk of concrete’s emissions come from this process. It’s estimated making cement and concrete is responsible for 5 to 8 per cent of emissions worldwide.

MOC is made from two byproducts from magnesium mining, magnesium oxide and magnesium chloride. The two chemicals can also be made from seawater.

It has so far been held back by its poor water resistance when turned into concrete, but associate professor of engineering at Western Sydney University Sarah Zhang and her team have discovered a method for improving the material.

Associate Professor Zhang said the discovery was significant.

“We think this is a breakthrough,” she said. “From the current research, no one can achieve such a high water resistance for MOC, particularly for warm water attack.”

The team added industrial byproducts fly ash and silica fume to the cement mixture, which improved its resistance in room temperature water.

To survive warm water, phosphoric acid and soluble phosphates were added.

Given a global need to cut emissions, Associate Professor Zhang said there was a large potential for uptake within construction industries. She said both Australian and international companies had approached her, interested in the material.

“Because we are aiming for more sustainability and a better environment, this material has a lot of potential to be adopted by industry, I believe,” she said.

Another factor preventing widespread uptake was its corrosive effect on steel, which meant traditional methods of reinforcing concrete using steel rebar were useless.

“We need to take some serious action to solve this big problem,” Associate Professor Zhang said.

The research has been welcomed by other experts.

University of Melbourne engineering professor Priyan Mendis said it was critical to tackle this challenge.

“Durability is a big issue with this when you use chlorides in concrete,” Professor Mendis said. “For me it’s a more critical problem for this concrete than this moisture issue.”

Professor Mendis said regulatory approval was another hurdle, which had so far held back geopolymer concrete, which uses resin instead of cement as a binding agent.

“I think the major barrier at the moment is authorities accepting this one and the construction companies putting it in their specifications,” he said. “We have to do some work to convince authorities to use these products.

“But it will be a bit harder because people are generally nervous when they see chlorides [because of the effect on steel].”

We recommend

We thought you might like

States

Capital Cities

Capital Cities - Rentals

Popular Areas

Allhomes

More