‘Living rocks’: Self-healing bio-concrete is on its way to Australian structures

Concrete that can repair itself by using a naturally occurring process could soon be used in Australian buildings and infrastructure, experts say.

Concrete degrades over time and can crack, which can be dangerous for a structure because it allows reinforcing steel bars to become corroded. This in turn further threatens the structural integrity of the building or piece of infrastructure, which needs to be sealed to prevent corrosion.

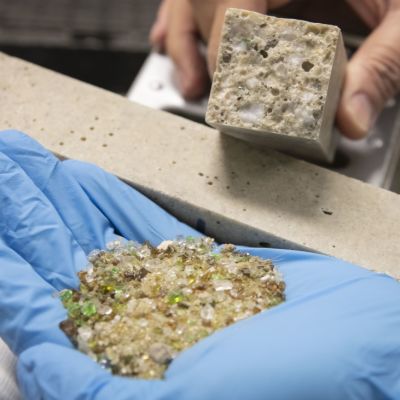

But scientists have found a way for concrete to self-heal under the right conditions, by adding biomineralisation-capable bacteria to cement and concrete to create bioconcrete.

It’s an improvement on current techniques to fix degraded structures.

Curtin University Professor Abhijit Mukherjee was developing the emerging construction product with his colleagues. He said some of their research had focused on finding suitable organisms that can live in the high-pH environment of concrete, and could stay dormant until needed.

“Inside concrete we use a microorganism that creates spores,” he said. “When you don’t give them food they clump together and die. But when you give them nutrients they come alive again.”

It is this organism that can heal the degraded or cracked concrete.

Professor Mukherjee said the bacteria were all naturally occurring and not genetically engineered. Some varieties performed better than others inside concrete.

“We just collect the bacteria and then grow them and then put them back into the cement. They’re natural and benign.”

One such location the organisms are harvested from are stromatolites off the coast of Western Australia.

“They are living rocks,” he said. “[Stromatolites] form because this bacteria converts calcium in the ocean water and carbon into calcium carbonate.”

Because the chemical make-up of the resulting stone includes carbon, the process also sequesters carbon, something necessary to help combat the unfolding climate crisis.

Professor Mukherjee said concrete could even be retrofitted to include the product.

“Once the cracking happens but before the corrosion happens, you can seal it with self-healing concrete,” he said. “Structures that have been built without the self-healing component can benefit from the technology.

“You can dissolve it in water and then add it to the concrete because water penetrates concrete and fills in the cracks.”

Professor Mukherjee said this was a better solution than some current methods, such as polymer seals.

“Concrete always has some level of moisture in it and a polymer will prevent the water from leaving which creates damage,” he said.

University of Melbourne Infrastructure Engineering Professor Priyan Mendis said self-healing concrete was of keen interest to researchers across the country. One issue that needed to be resolved was what impact the improvement had on strength of the material.

“We’re trying to find the best and most efficient way of doing it. We know it works,” he said. “Once we use these additional materials, we need to be careful about the reduction in strengths and mechanical properties. We need to be careful we don’t compromise on that.

“We need to do new research around this.”

Professor Mendis said once commercialised, it should take off.

“They are natural products and freely available. I don’t think it will be expensive, we just need more research and it should be very popular,” he said.

While some researchers hope to use bioconcrete to “grow” concrete structures, Professor Mukherjee has his doubts.

“You can create structure with this but I don’t see it replacing cement,” he said. “You can apply it in an area where there is maximum benefit from [concrete being able to self-heal cracks].

“It gives concrete a longer life.”

We recommend

States

Capital Cities

Capital Cities - Rentals

Popular Areas

Allhomes

More