Why scientists are putting old tyres and broken glass into concrete

Scientists and environmentalists are turning to unconventional materials to make concrete in an effort to reduce waste in landfill and the building material’s impact on the environment.

Crushed, worn-out tyres are emerging as a good replacement for some of the sand used in concrete, with researchers saying it can even improve its properties.

University of South Australia Pro-vice-chancellor Julie Mills said crumbed rubber concrete (CRC) was weaker than conventional concrete in some ways, but the trade-off was well worth it.

“The downside is it loses its strength from a compression point of view but it increases its impact strength and crack resistance,” she said.

It also made the concrete more flexible, which was useful in CRC’s targeted use – concrete footing for residential houses.

“Half of readymade concrete goes into residential footing,” Professor Mills said. “There’s wide application so if it works there’s a big market for it and the second thing is residential construction doesn’t require high-strength concrete.”

She said it was particularly important in some parts of Australia to have a flexible footing under a home, because soil movement was more common than in other parts of the world.

Professor Mills has been researching CRC with the support of Tyre Stewardship Australia, an organisation dedicated to reducing the used-tyre waste.

TSA chief executive Lina Goodman said that as the sand used in concrete became more scarce, finding alternatives would become vital.

“These results are significant not only for Australia but the international construction industry. Concrete is the single most widely used material in the world,” she said. “This project aims to reduce the environmental impacts of both waste tyres and harvesting of natural resources.

“The Australian residential construction industry is a substantial market, big enough to consume much of the recycled rubber from Australian waste tyres if CRC can be adopted.”

Professor Mills said this was likely because the price for the rare sand used in concrete was rising rapidly, which would increase the attractiveness of CRC.

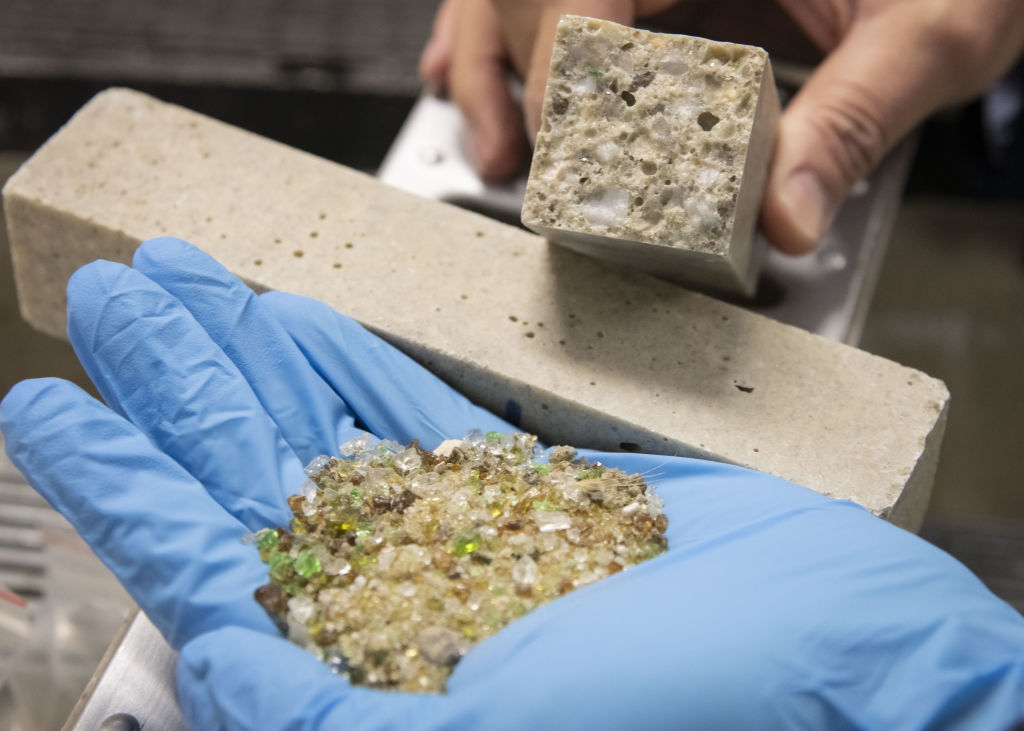

At Deakin University, researchers were investigating the viability of using crushed glass in polymer concrete, with the potential for it to be used in conventional concrete down the line.

Polymer concrete is made from resin instead of cement and is more widely used in industrial settings than residential.

Senior engineering lecturer Riyadh Al-Ameri said using glass made the polymer concrete stronger and cheaper.

“We give experimental evidence that shows this glass can be used instead of sand in polymer concrete,” he said. “It will be more durable. We are able to now show that we can replace 20 per cent of sand with glass.”

While glass could usually be recycled, Dr Al-Ameri had specifically targeted waste that would have otherwise have ended up in landfill.

“The glass used is made from tiny particles which are too small to be sorted and may be contaminated with lead and can’t be used in new products,” he said. “It would be glass that might have to go to landfill.

“We are planning to replace the coarse aggregate as well.”

Dr Al-Ameri said future research could look to find uses for plastics in concrete too.

“We are hoping to have some new innovative construction materials which will be more sustainable and help the circular economies, which is a strategic outcome of ours.”

We recommend

States

Capital Cities

Capital Cities - Rentals

Popular Areas

Allhomes

More